Are you building too much resilience into your business?

In response to recent disruptions in their supply chains, many businesses have invested heavily in developing increased resilience – more inventory (just as likely to hide the true problem as buffer the disruption), supplier risk assessments, reshoring, digital ‘control towers’, multiple alternate distribution routes and partners etc.

However, all of these measures add cost. Aiming for the top level against any of the readily available checklists (we’ve created one that you can access through the link below), can drive your organisation towards a state of “perfection” that may be unnecessary and even bad for your business.

Cruise ship or ocean liner?

So, before you rush off to grab the checklist, consider this more important question. “How much resilience do we really need to achieve our business goals?”

To clarify what we mean here, consider a cruise ship. Most are designed to operate in reasonably good weather, able to cope with moderate storms and so on. After all, who’d want to cruise in a hurricane? Only one, as I read recently, is designed to cross the North Atlantic in winter – the Queen Mary 2. I

She’s a true ocean liner like the great ships of old. You can see it in her design – smaller windows, a thicker, stronger hull, greater speed, and more powerful propulsion for rough weather conditions. Not to mention a crew prepared to provide excellent customer service in challenging conditions and also to deal with any more difficult situations that may arise. Readiness for the Southampton to New York run will have influenced the design of all her systems. But at what cost? The cost of steel alone was around 40% more than a conventional cruise ship.

If all cruise ships were built to this standard, imagine the expense and impact on the cruise line’s profitability. Would some of the huge cruise ships with massive superstructures we see today even stay afloat? Instead, the cruise lines plan their itineraries around the weather conditions and keep their ships well away from the worst of the Atlantic weather and hurricane season.

Bottom line, each type of ship has a level of resilience and adaptability that is suited to its intended purpose. There is no single standard that can be applied in every circumstance.

What level of resilience does your business really need?

In the same way, there is no absolute definition of what level of resilience and agility is required in a business. It all depends on what “seas” you plan to operate in.

So, instead of rushing out to invest in all the latest technology and process development, consider what you really need.

For example:

Strategy: are we building a long–term sustainable business or seeking to maximise short–term return in the current conditions?

Supply network design: are we looking for lowest cost with higher risk or more certain supply?

Manufacturing flexibility and capacity: how much and how quickly do we need to be able to respond to changes in markets or adjust to variable supply performance?

Technology: how much do we invest in automation, IT systems etc to reduce dependence on labour availability and capability?

Demand and inventory management: how much variability of supply and demand do we need to be able to cope with?

Financial management: how much cash do we want to hold or invest to mitigate risk?

Workforce and organisation agility: are our workforce merely resources to be used or a treasure whose capability and adaptability we need to grow for long–term security and success?

All of the above will involve some trade off between cost and the level of uncertainty that can be managed. However, there are good and bad trade–offs. The best organisations approach this challenge with a “both…and…” rather than a “either…or…” mindset that leads them to think creatively about how they can achieve a better solution without excessive cost.

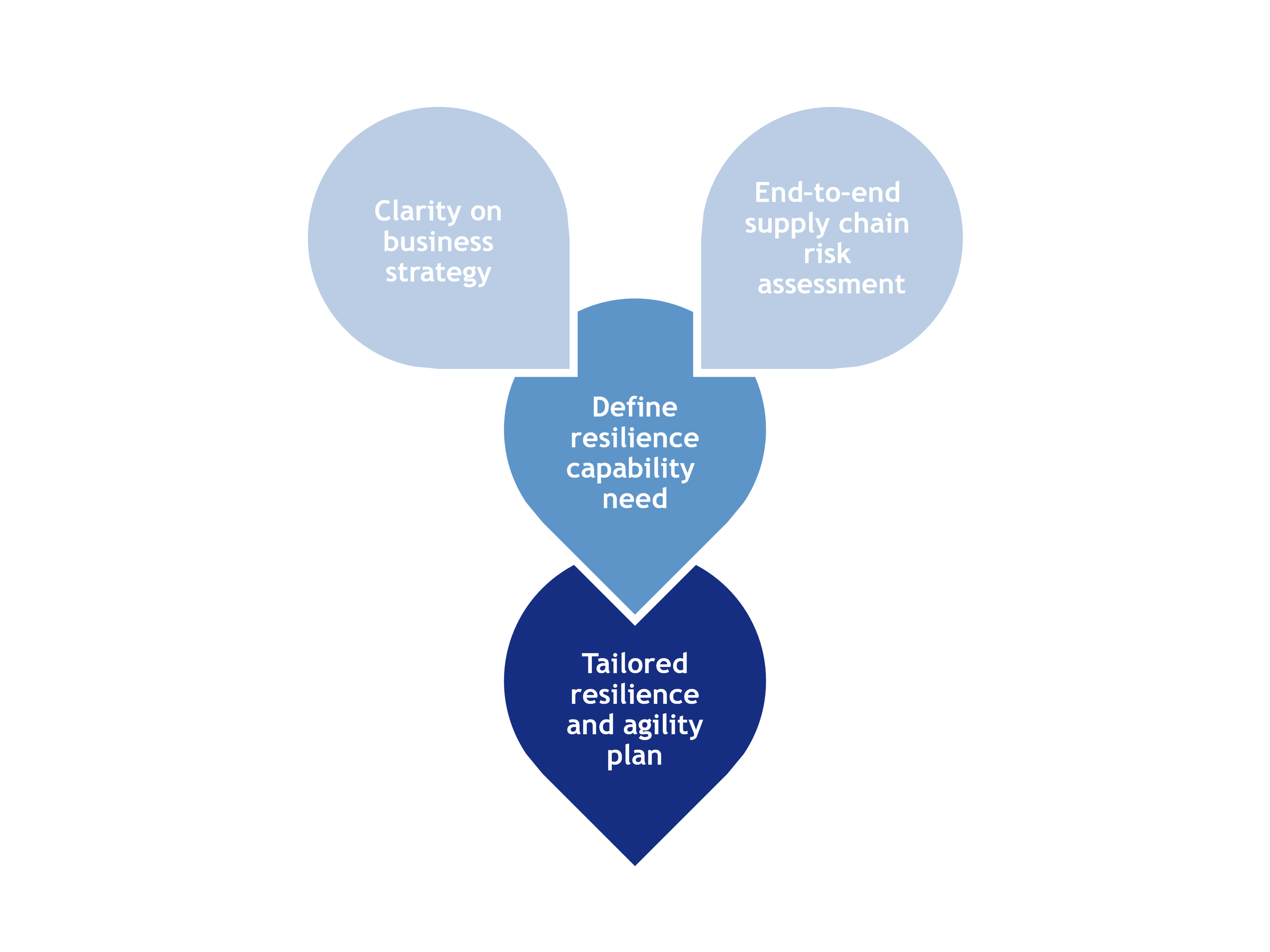

A systematic approach to building a robust resilience and agility capability

A systematic approach

Getting the right approach for your business requires a more comprehensive approach that looks at resilience in relation to your overall business objectives and the likely risks in your end–to–end supply chain. Only with this information can you define the actions required to make your “ship” ready for the voyages it is intended to take. We advocate a four-step approach as shown.

What would help you most now?

Learning more about exactly what is involved to work through the steps in the above process? We have a step–by–step guide.

A process to help you see how well your organisation performs currently in terms of resilience and agility? Use our self-assessment tool – it’s free and you won't need to enter any contact details to access it.

An example of how one Japanese company – that I witnessed first–hand on my Japan trip last year –has taken a multi-generational approach to sustainability, through building its resilience capability, that has seen it through some major changes to its business environment?

You’ll find all of these on our website by clicking the link below.