Resilience and Agility

“Resilience is the capacity to recover quickly from difficulties; it’s not about avoiding the storm, but learning to dance in the rain.”

Unknown

How much resilience do you really need to achieve your business goals?

An effective resilience and agility plan is best tailored to the real needs of your business rather than from comparing your organisation to some ‘absolute’ standard that considers all sorts of possible resilience measures.

Without such an approach, you may be adding costly measures into your business that may adversely affect your business or even be completely unnecessary.

A systematic approach to finding the right resilience and agility plan for your business

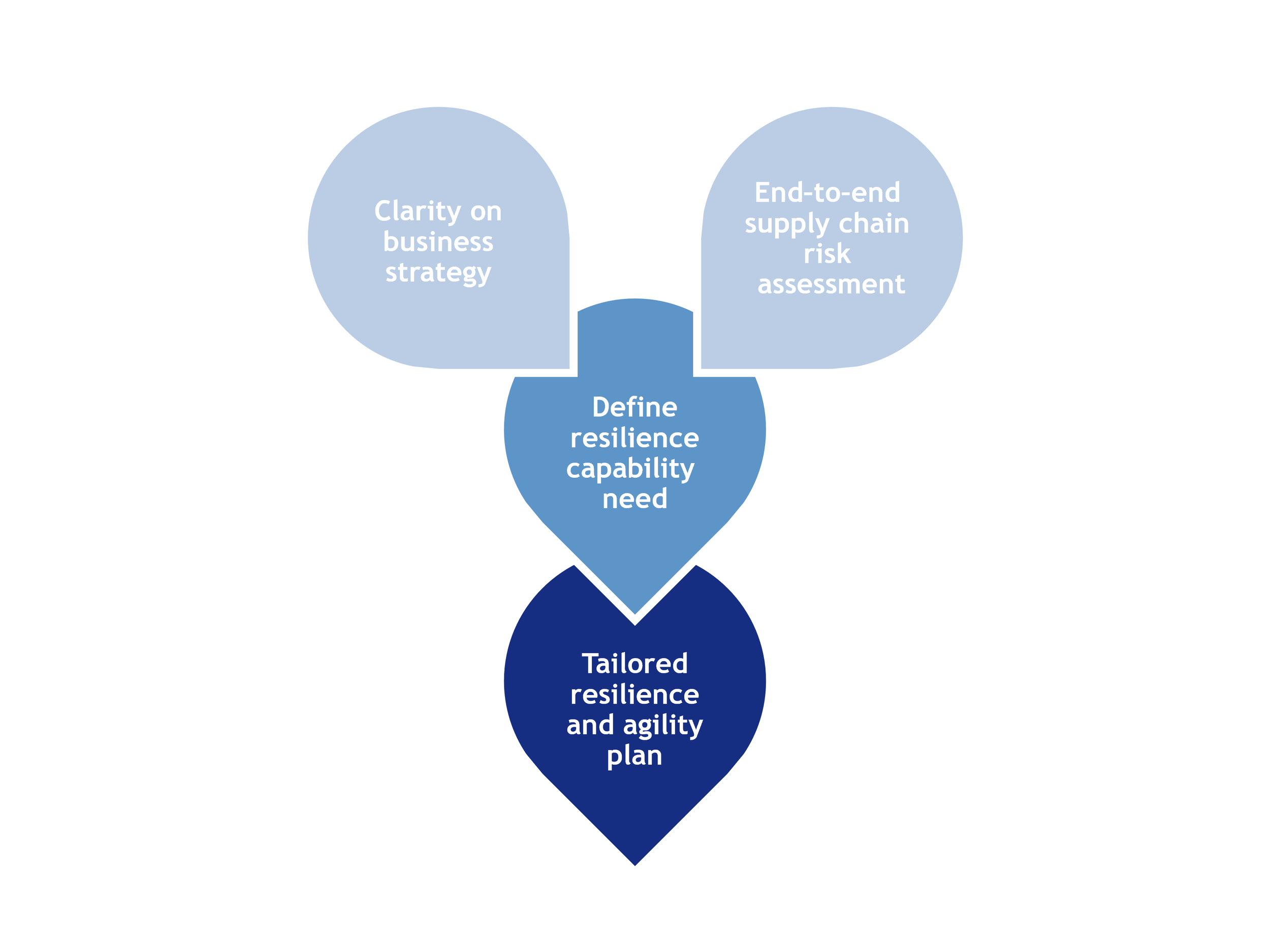

We adopt a four–step process that examines both strategic goals and supply chain risk to determine your true resilience need, against which you can then compare your current capability.

The big question here is “how much resilience do you need?” Are you simply looking to weather the storms likely to impact your current business in the short–term or aiming to build long–term sustainability for your business as customer needs and market conditions evolve over several generations?

Identifying risks to your business is the next step. The specific levels of evaluation will be influenced by your answers to the above, but the approach and start point is always the same.

Create a ‘map’ of your end–to–end supply chain. A comprehensive map would include everything from extraction of raw materials to your end customer and include the transport links in–between.

2. Consider the risks associated with every element of the map. This can use a combination of the principles of:

a) Business Continuity planning: this considers the question “what would be the impact of that element being unavailable?” without considering causes. This creates the broadest possible consideration of potential disruption to your network and consideration of alternative provision

b) Failure Modes and Effects Analysis (FMEA): a technique commonly used in product and production system development, this technique considers more dimensions than a conventional risk analysis.

i) Identify the RISKS at each point in the network to delivery time, cost, security of supply etc?

ii) For each risk consider:

– What is the likely IMPACT of each event?

– How LIKELY is that to occur?

– How DETECTABLE is the risk, ie what indications will we see, how much notice will we get?

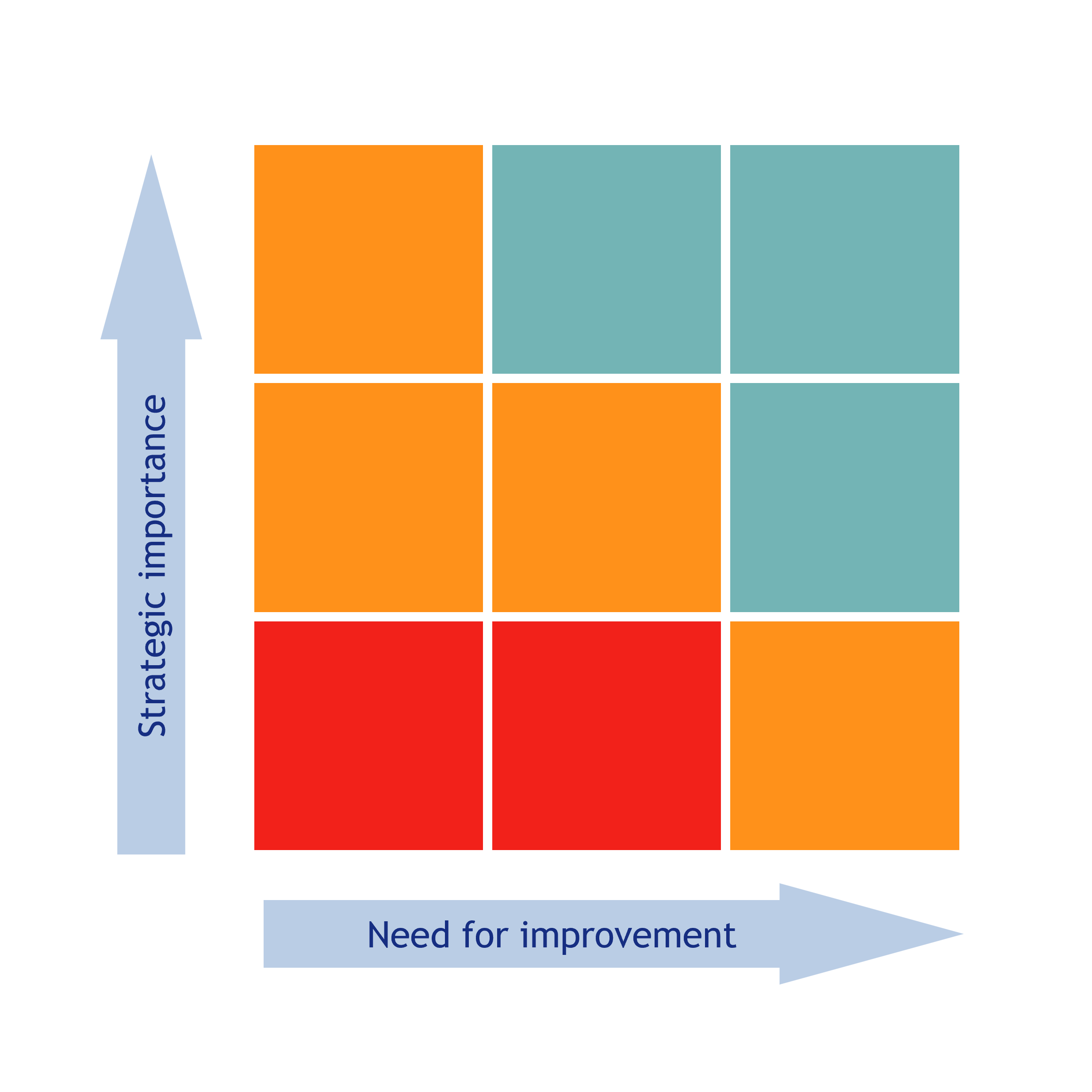

Scoring each of the above can be on a numerical scale (1–10) or, more simply High, Medium, Low. The combination of Impact, Likelihood and Detectability compared to how strategically significant that aspect is, suggests how important it is to take action.

For those risks requiring action, consider what MITIGATION can be put in place to either reduce the risk or be more prepared to respond should the event occur?

A simple assessment tool examines a range of possible elements of a resilience plan and can be used to suggest possible mitigation actions. It invites you to consider the extent to which each element is necessary given the considerations above and assess how they are currently present in your organisation.

From the completed assessment a prioritised matrix is created, from which an action plan is developed to ensure that improvements are carried out in the most appropriate order.

To complete this process well takes time and needs to involve a wide range of people to ensure that the full spectrum of risk is considered. Objective expert facilitation can be of great help here.

We have facilitated many similar workshops for clients over the years and would be delighted to support you to create the most appropriate resilience and agility plan for your business.

The benefits

With the right resilience plan in place, your business can have:

An affordable resilience and agility plan that is appropriate for your business strategy and does not adversely affect your profitability

A supply chain that is significantly less prone to interruptions

Reduced exposure to supplier risks, for example, through a diversified supply chain

A future–proof supply chain that remains responsive and agile in challenging circumstances

More significantly, you will have a deeper understanding of the (often unacknowledged) assumptions implicit in the design of your current end–to–end supply chain and be able to adapt it appropriately to respond to future disruption in the most appropriate way.

How can we help?

If you’d like to explore how we can help you build a “right-sized” resilience and agility plan for your business, the best next step is a free, no obligation call. No sales pitch, just an open conversation to understand you and your business better and see where we can help.

Use the button below to book a call or fill in our contact form and we’ll be in touch.

One of the companies I was privileged to visit on my Japan trip last year had a true long term perspective on resilience, driven by its founder’s philosophy of operating on the basis of inevitable change.

"The job we do now will be taken over by somebody

or something else some day!".Kazuaki Kato, Founder, AVEX INC, JAPAN

Rather than seeing changes in its business environment as a threat, it embraces them as an opportunity to grow and develop its resilience and agility. This approach has served it well since 1949 and is set to continue doing so well into the future.

Starting as a manufacturer of sewing machine needles for Toyota, it evolved into making brake parts when Toyota’s sewing machine business moved overseas. Next it moved into manufacture of precision machined parts for automatic gearboxes, at the same time reducing its dependence on Toyota. The company has grown consistently over that period.

Now, having weathered the storms of the 2008 financial crisis and the Covid pandemic, it is transforming its business again as demand for its current products reduces due to the adoption of electric vehicle. This time it's looking to broaden its customer base again beyond automotive.

At the core of this ability to transform is its commitment to its people. Rather than seeing them simply as a resource or asset, it describes them as its “treasure” – to be valued and cared for. Thus, rather than reduce headcount in recent crises it chose the harder path of retaining people and using the time to grow their capability and skills to increase the adaptability of the workforce to face the anticipated challenges.

They are confident that this approach will see them into the next generation with greater strength and increased competitiveness in the global marketplace.