Improve Customer Service

Bringing the two dimensions of your business – strategy and execution – into alignment is key to long term success

However clear your Customer Service Strategy is, without an effective ‘operating model’ to put it into practice it be no more than a pipe dream A truly effective operating model requires a ‘whole system’ approach, aligning all parts of the business to deliver on the strategy in a way that achieves what we term as ‘high performance with ease’.

The following example illustrates how we helped one client execute their customer service strategy in ways that enhanced cash flow, optimised inventory, and took production planning and execution to a new level of performance.

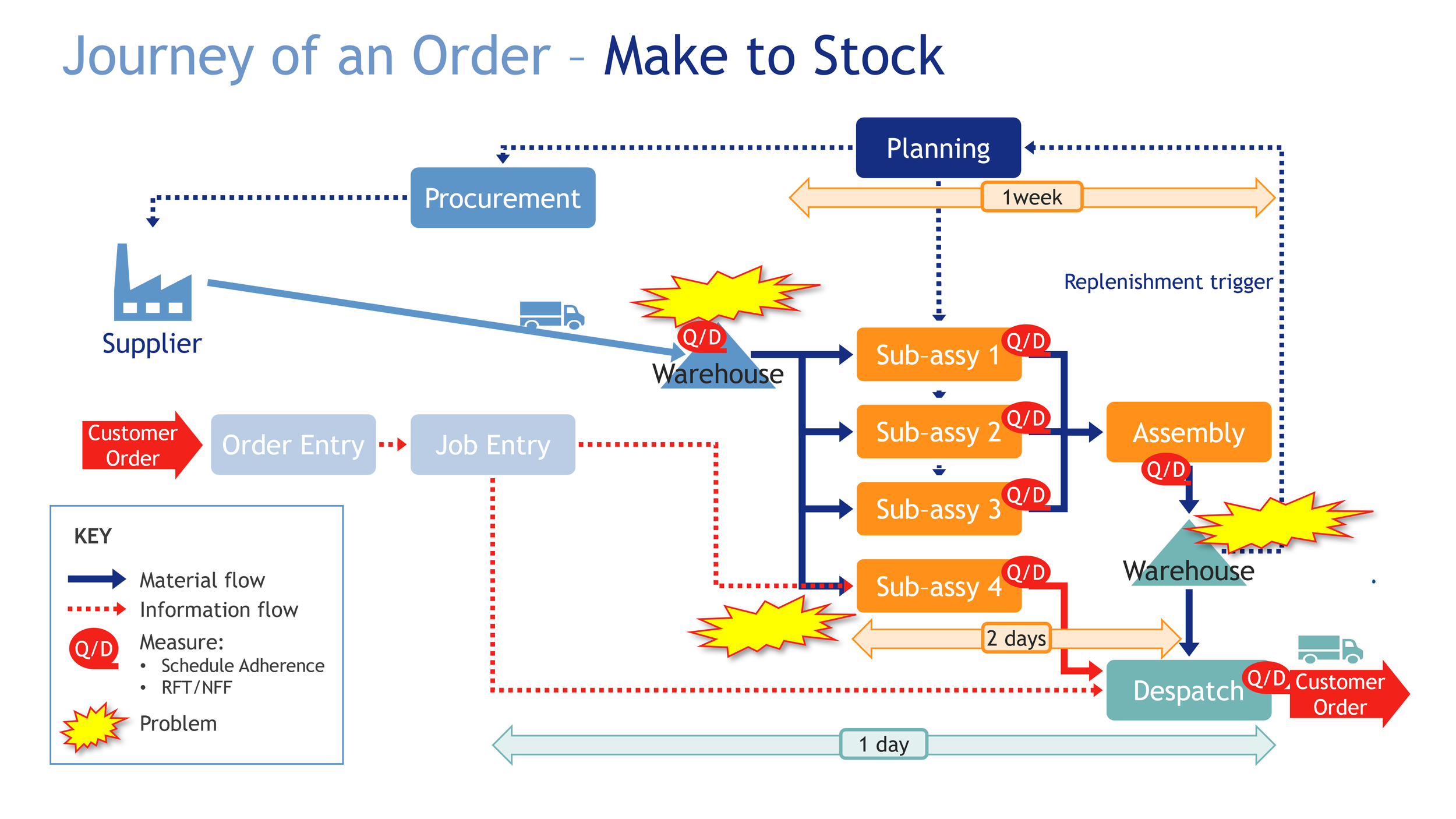

1.The standard product - Make to Stock

Offering a next day despatch service requires either sufficient inventory to satisfy customer orders ‘X’% of the time (100% is virtually impossible or hugely expensive) or the ability to make the product quickly. In this case, making the product quickly enough was not an option, so we:

Defined an inventory profile (max and min levels) for purchased materials and finished goods to ensure that items were available for despatch and inventory replenished to meet the pattern of demand (based on a statistical analysis of sales).

Defined a production planning process that responded to inventory triggers to replenish stocks of the standard items (pull system).

Ensured that production planning, warehouse, procurement and production understood the intent of the operating model and had processes aligned to it.

Involved sales to mitigate the potential impact of occasional large orders (revealed during the analysis) by, for example, exploring the option to align deliveries against a single large order to the intended usage pattern rather than having to deliver the whole order as one lot.

2. Custom products - Make to Order

Custom products were made to order, requiring varying levels of bespoke design as well as manufacture. We organised workshops between the various functions involved to map out the end–to–end process from enquiry to installation, ensuring that procurement and production were involved early enough in the process to influence the design (for supplier selection and production method) and be ready to order materials and plan production to ensure that the quoted lead time could be met.

Example: Differentiating your operating model for different products / service level

A client had two different product offerings:

1. A standard product in a range of sizes offered on a ‘next day despatch’ basis

2. Custom products that were designed and made to customer specific requirements

While both were produced in the same factory, each required a very different ‘operating model’ that required very different things from multiple areas of the business. The ‘operating rules’ for each area involved had to be aligned and interlinked to ensure smooth operation.

3. Production planning

Since both products used the same production facilities and staff, it was necessary to define a production planning process that accommodated the needs of both product types. In order to achieve a more balanced workload in production, this led to a slight increase in stockholding for standard items to allow for fluctuation up and down in demand for both standard and custom products, allowing more standard product to be made when custom demand was low and sufficient stock to satisfy standard orders when custom demand was high.

Ready to explore further?

If you’re interested in exploring how this approach could help you to improve the convergence of your operating model with your customer service strategy, the first step is a free, no obligation call to explore your current business situation and identify specific ways in which we might help. Just click the button below to book or fill in our contact form and we’ll be in touch.

Want to learn more?

For more information, click the links.